Industrial equipment health management is an important part of the information and digital transformation of manufacturing enterprises.

Manufacturing enterprises have a wide variety of industrial equipment, industrial protocols, and complex application scenarios. Traditional industrial equipment management mostly adopts regular maintenance and post-disaster repair modes, which have problems such as difficult equipment management, heavy downtime losses, high maintenance costs, scattered information, high communication costs, untimely execution, untraceable data, and no decision-making management support, affecting enterprise production efficiency and product quality, and significantly increasing the operating costs of enterprises.

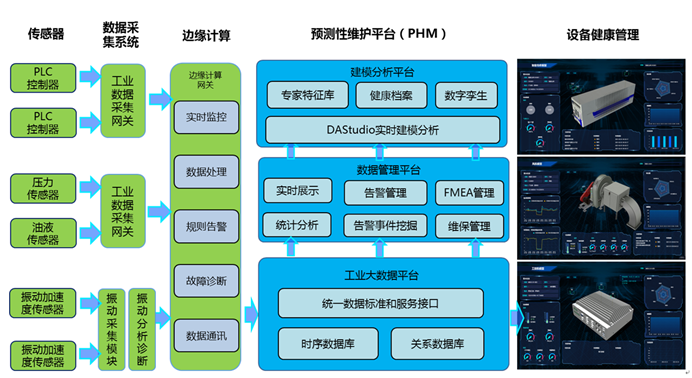

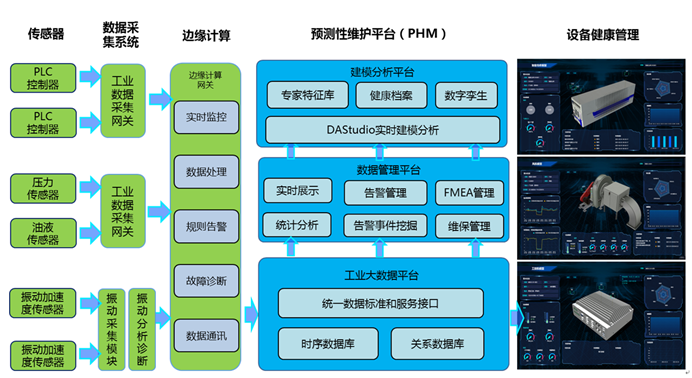

Based on the industrial Internet platform and 5G network, the NICIEI is established to provide equipment health management and fault prediction PHM system solutions, providing real-time status monitoring of key equipment, equipment and indicator management, historical data query, indicator-based fault diagnosis and alarm management, unified operation and maintenance strategy, fault expert feature library, equipment health file management, 3D visualization, etc. It builds multi-dimensional and real-time health indicators to comprehensively reflect the health status of equipment by means of radar diagram.

At present, the equipment health management and fault prediction PHM system solution has been applied and deployed in an automation equipment plant. It realizes real-time monitoring of equipment operation status in the equipment plant and anticipates equipment operation status; intelligently locates faults according to monitoring results, prepares spare parts in advance, and improves maintenance efficiency by 70%; carries out remote maintenance, saves personnel travel expenses, and can accurately and quickly eliminate faults, reducing downtime and maintenance costs.

The above pictures come from the network, if there is any infringement, please contact to delete, thank you!